Stage 03: Medicinal Cannabis Flowering Stage

Flowering

The Medicinal Cannabis Flowering stage is the 3rd stage in the medicinal cannabis production process. The first 1 to 3 weeks of the flowering stage are a transition phase, during which the plants could double in height. After the buds appear the plant will stop growing and will put all its energy into the flowers and the cannabinoids.

Optimum flowering conditions

Cannabis plants start flowering when they are exposed to equal hours of night and day. Prior to this stage, the plants should be given 18+ hours of light to encourage maximum growth. A facility control system such as Argus, gradually changes the light cycle until a 50/50 ratio is reached, i.e. 12 hours light and 12 hours dark. The system could also change the spectra of LED lights between the vegetative and flowering phases, but this is unusual.

As the flower house is where the plants spend most of their time (60-70 days), it’s important to optimize all conditions. Cultivars that have a 60-day flowering cycles will typically deliver up to six crops per year. Achieving the highest yield of both flower volume and concentration of the active ingredients are highly dependent on the strain, the skill of the grower and the conditions in the flower house. Nutrients, light, temperature, humidity and CO2 levels must all be precisely controlled through the facility control system.

360° panorama – drag the cursor around the image to view the layout, for full screen choose the icon in the bottom right corner.

Flower house processes

The medicinal cannabis flowering stage is very labour-intensive. Physically moving the plants between the vegetative stage and the flowering stage areas presents many manual handling issues. The process should be carefully designed to use as much automation as possible, both to keep labour costs down and to prevent injuries to workers.

During the 60-70 day flowering phase, a visual inspection of the plants to check for diseases, pests and general health should be done up to three times a day. Workers must also manually train the plants onto support structures. This prevents the plants from collapsing under the weight of the flowers. The support structure must also be built to ensure good air circulation through the plants, which reduces the risk of disease.

Each cannabis strain requires different lighting for optimum growth and consideration must be given to all sources of light in the facility – including illuminated exit signage and task-based lighting used by workers, usually green.

Regulations

The propagation of cannabis plants is regulated by the Australian Office of Drug Control. You must hold a licence from them to cultivate cannabis. During the cultivation phase of cannabis the Australian Office of Drug Control are the regulatory authority. Once the plant has been harvested and moved into the manufacturing stage of the final medicinal product then the Australian Therapeutic Goods Administration (TGA) regulations could apply. This part of the manufacturing process must comply with the current Good Manufacturing Practice (cGMP) guidelines. These rules are designed to ensure the safety and efficacy of all pharmaceutical drugs sold. The rules cover everything from facility design through manufacturing processes to the packaging, labelling, storage and transport of the final drug product.

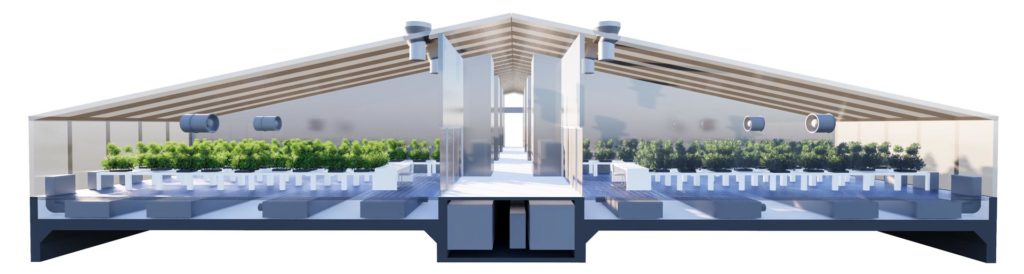

Cannabis Green House Design

When designing the Cannabis Green House Design to grow medicinal cannabis facility, it’s important to consider a number of factors:

- Whether to grow under glass, under plastic or indoors: Growing indoors allows you to control all the conditions to achieve the best crop, but must be offset against the capital cost of setting up the facility. Growing under glass / poly-carbonate provides the most control but is also the most expensive facility to build.

- Whether to purpose-build a facility or to retrofit an existing plant propagation facility. PharmOut has strong opinions on this one – based on experience!

- All light sources in the flower house. Even exposure to illuminated signage of the wrong type of light from a worker’s torch can be enough to impact the plants.

- Consideration should be given to the fact that even minor changes to macronutrients, temperature or even humidity, can impact the cannabinoid profile.

Services PharmOut offers:

PharmOut can design a complete turn-key solution, or you may need help with only specific areas, such as:

- Design of the head house

- The whole of the cannabis grow house design

- Design of pharmaceutical facilities

- Design of the workflows and processes to minimise labour costs

- Design of personnel, material, waste flows and contamination control strategies

- Design of the required security system

- Selection of equipment and staff

Get in Touch

If you would like to learn more about our services, request a quote or ask any questions please fill out our enquiry form here.