Lean Pharma Plant Design

Lean Pharma Tips

I think everyone has heard of the 7 Lean Manufacturing Wastes, increasingly we hear that an 8th Waste has been added – Skill.

Over the years, and with my failing memory, I have learnt that I need an easy way to remember the “wastes”, especially when I’m out front training a class, so my tip is if you remember that they spell TIM WOODS you should be okay –

T : Transport – Moving people, materials and even empty vehicles

I : Inventory – Storing work in progress, work pieces, documentation ahead of requirements

M : Motion – Walking, bending, lifting, turning, reaching

W – Waiting – manufacturing instructions, equipment or raw materials

O – Over production – Making more than is IMMEDIATELY needed

O – Over processing – Tighter tolerances or higher grade materials than are necessary

D – Defects – Rework, scrap, incorrect documentation

S – Skills – Under utilizing capabilities, delegating tasks to staff with inadequate training

Lean Pharma Plant Design

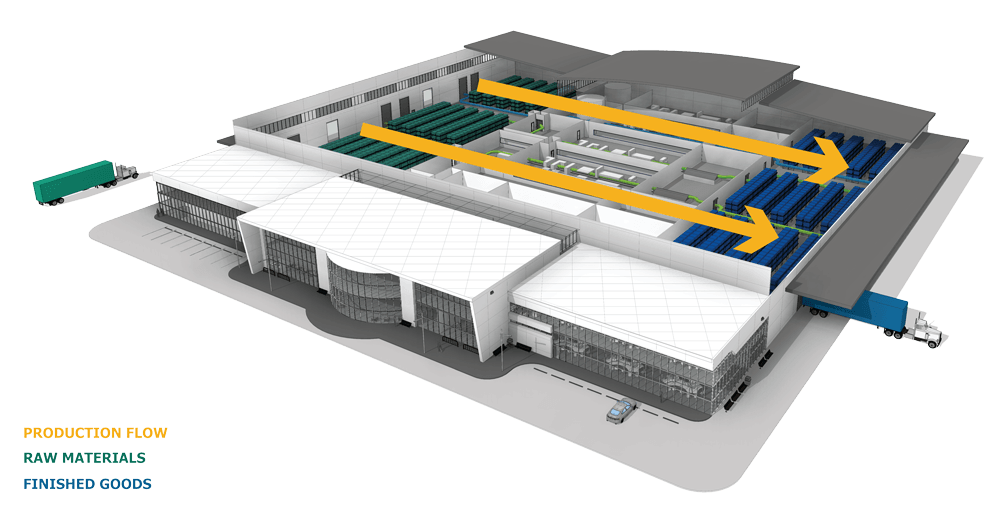

Often pharmaceutical GMPs and Lean objectives are counter intuitive, take for example a very basic requirement of unidirectional flow for a factory (low risk products), the classic text book design is to have the raw materials entering the facility on the left (as in the case below) and leaving on the right hand side.

It is critical to design the facility correctly from the outset, often a rubbing out of a line at concept stage is a 1000x cheaper that at the final project stages.

The GMP compliant design

The problem with this “GMP compliant design” is that as the sales demand is high and capacity there is temporary reduction through a product mix change or a machine break down, there could be increased stock sitting in the green raw material and the finished goods warehouse is empty. Shifting materials around, is a waste.

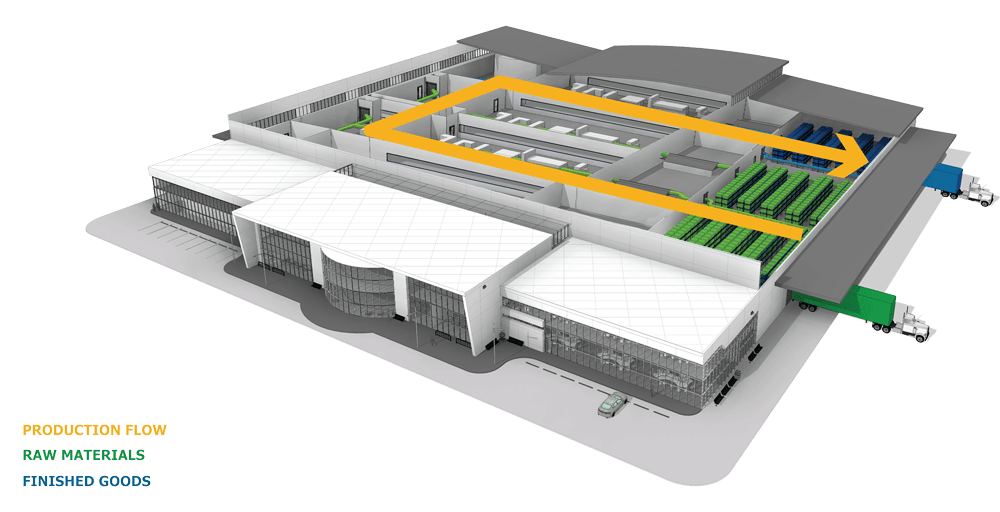

One way to overcome this problem is to have a U shaped plant design, this means awnings, dock levelers, road access and traffic flow is usually safer for your staff, i.e. their paths do not cross.

U Shaped Plant Design

In this example, you can see that the raw materials and finished goods share a common site access point, ramps, doors and dock levelers, and most importantly, the raw material and finished goods spaces can be expanded or contracted to suit real world changes. Obviously, returns, rejected and labels need to be securely stored.

It is common in regions of the world where land is a premium, I would recommend the use of “lights out” warehouses (or chaos warehouses), this system could offer a practical win for a client.

Increasingly, we are seeing Lean Manufacturing principles being applied to Pharmaceutical plants and Pharmacies, but there needs to be a sensible balance to ensure compliance and a sound understanding of both. Hopefully, this almost oversimplified example will encourage you to get a professional design, using PharmOut’s architects, engineers and GMP compliance experts as well as modern BIM tools, if not at least get an independent design review by PharmOut before you start pouring concrete on your next project.